Benefits and Advantages of Manufacturing in Mexico

Manufacturing isn’t all done by robots and automation: US businesses still rely heavily on labor to produce goods that their customers need, and this can become a problem.

Long-term employees are retiring, younger people seem uninterested in factory work, and employment costs are rising. One solution is to have more work done in Mexico.

Here’s a look at how this can benefit businesses in the US, and a short explanation on how to go about making it happen:

BENEFITS AND ADVANTAGES

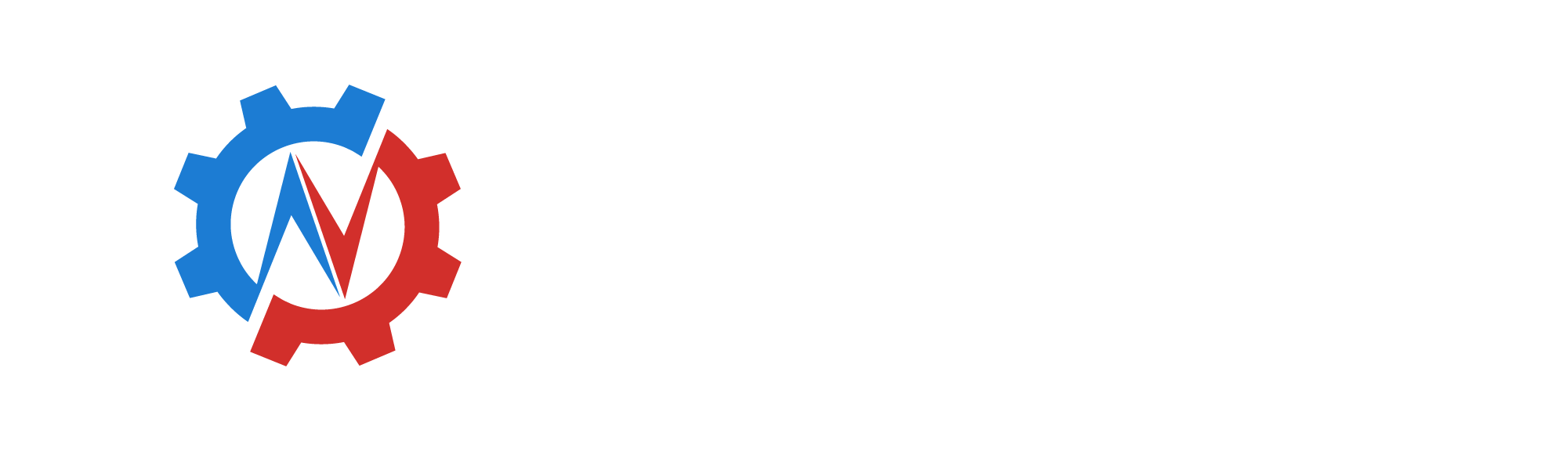

Lower Cost Labor

Wage costs at almost all levels, but especially for manufacturing workers, are significantly lower in Mexico than in the US. In January 2020 the Federal Reserve Bank of St Louis put average earnings of US manufacturing workers at $22.45/hr. In Mexico the fully burdened figure is closer to $4/hr.

Hourly costs don’t tell the whole story of course: productivity matters, and Mexico is doing well in that regard too. To quote from “The Shifting Economics of Global Manufacturing” (Boston Consulting Group,) “We estimate that Mexico now has lower average manufacturing costs than China on a unit-cost basis.”

Moving away from the factory floor, salaries for skilled technical personnel and managerial grades are closer to, but still lower than, those in the US. In short, all manufacturers can benefit from lower labor costs in Mexico, especially those where labor currently makes up a large portion of their total costs.

Lower Non-Labor Costs

Proximity to the US minimizes the cost of bringing manufactured goods north of the border (unlike manufacturing in Asia which requires a long and costly sea journey.) Healthcare costs are low, and factory space is a fraction of what it costs in the US.

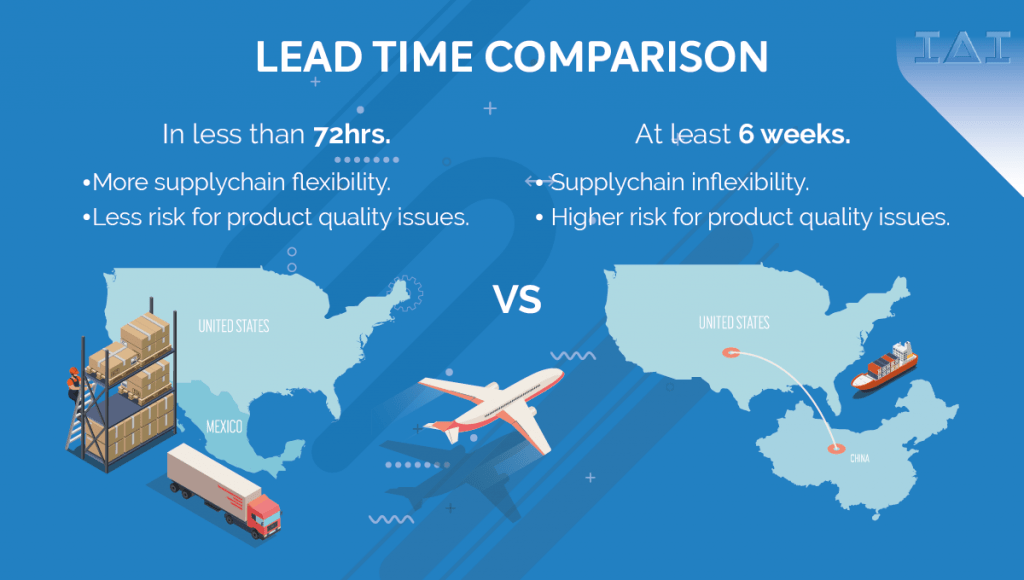

Short Supply Chains (Compared to Asia)

The US-Mexico border is one of the busiest in the world with a constant flow of trucks and trains in both directions. A product made in Matamoros, or Ciudad Juarez, today can be on a factory assembly line, and in less than 72 hours it can be in a warehouse or on a store shelf in almost anywhere in the US.

Besides reducing inventory and working capital, short supply chains increase flexibility and help avoid quality issues. If demand changes or a defect is found, there’s far less product in the pipeline to sort and perhaps discount.

Free Trade Agreements

NAFTA removed many of the barriers to trade between the Mexico and the US. IMMEX established the maquiladora program, and more recently, the USMCA agreement has helped streamline the flow of goods and services across the border. While hold-ups can occur if documentation is incomplete, delays at the border are very uncommon.

Availability of Technical Specialists

Automation reduces labor costs, but requires high levels of technical support for implementation and maintenance. Obtaining these skills is a growing challenge for manufacturers in the US as experienced engineers retire, and younger talent is scooped up by Silicon Valley. However, Mexican universities are graduating over 100,000 engineers each year, providing a healthy pool of young technical specialists.

US Quality Levels

Mexican manufacturers are well-versed in Quality Management Systems like ISO 9000 and 16949, and understand how to meet the requirements of demanding customers in industries like automotive and aerospace.

Furthermore, Mexico rates highly for K-12 education spending, (as assessed by the Brookings Institute “Global Manufacturing Scorecard“,) ensuring good availability of highly capable manufacturing workers.

Respect for IP

Intellectual Property theft is a valid concern for US manufacturers looking to move production to lower cost locations. Some countries have a poor reputation in this regard, but not so Mexico. Mexico has a strong independent legal system and gives patents and trademarks the same level of respect they receive in the US. Business owners and managers choosing to source from or set up in Mexico need not have concerns about losing control over their IP.

HOW TO ESTABLISH A MANUFACTURING OPERATION IN MEXICO?

Starting from scratch is difficult. There are premises to find, staff to hire and a host of local regulations to comply with. It’s all possible to handle, but it will take time. Non the less, here are 3 Proven Strategies to Start Manufacturing in Mexico.

But there is a compelling reason why many manufacturers making an initial foray into Mexico choose to work with a manufacturing services company like The Nearshore Company.

IAI offers a wide range of services, but in essence, provides all the resources necessary to start manufacturing in Mexico. This ranges from taking care of all legal and tax issues to providing a building, hiring staff and even setting up the production operations.

Once you’ve decided to have some or all of your manufacturing done in Mexico, the faster the operation is up and running the sooner you’re saving money. Try to do all that yourself and it could take many months. IAI cuts that time dramatically. Plus, it lets you maintain focus on running your business rather than getting drawn into the details of setting up the new operation.

Secure a competitive advantage for your company and let us help you transfer your operation into Mexico in the most seamless way.